Quality derived from strict adherence to procedures and production processes, from receipt of raw materials to delivery of products to our customers, and on the strict quality control of finished products after and during manufacture.

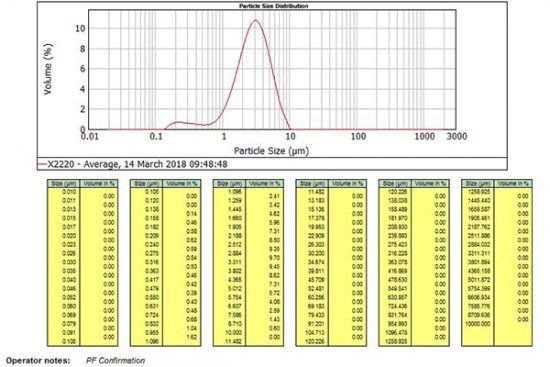

Equipment: electronic densimeters, Brookfield viscometers, AFNOR or FORD cups, ovens and scales, electronic pH meters, infra-red, gas chromatograph, laser particle size analyzer, rheometer, visible UV spectrophotometer, muffle furnace up to 1000°C, measurement rupture force.

1

Raw material controls

Rigid and systematic checks of supplier Certificates of Analysis, specific, independent controls on certain key materials (IR, refractive index, density, aspects,…)

2

Finished product inspections

Strict plant operator process control, in-process QC, final QC (moisture content, viscosity, density, particle size, film-forming aspects on plate, ash content, pH, infra-red, gas chromatograph if needed) etc.