Our equipment can meet the specific technical data of our industrial partners.

Our technologies are :

-

High viscosity up to 500,000 mPas

-

Temperature up to 160°C (steam)

-

Pressure up to 5 bar

-

Rotation speed up to 1500 rpm

-

26 production lines – some can be dedicated

-

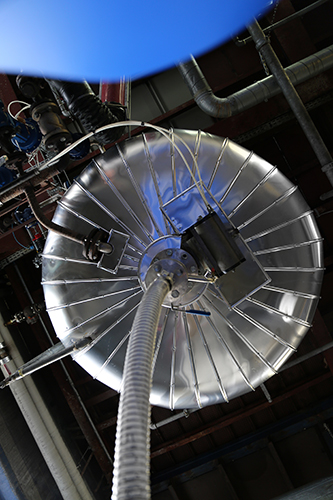

Reactors from 1m3 to 35m3, most of them being ATEX

-

Stainless steel material – One 1000 l glass-lined reactor

-

Grinders : 3 ball mills

sous-traitance